Naval Interiors: Digitalization, IoT, and big data merge with craftsmanship

Optimising production processes by directly connecting design and artisanal phases in real-time: that’s one of the great innovations and achievements of Industry 4.0, which has also made its way into our laboratories and production lines. Yes, because we enjoy challenges, especially those that project us into the future.

Cruise 4.0 and the Importance of Details

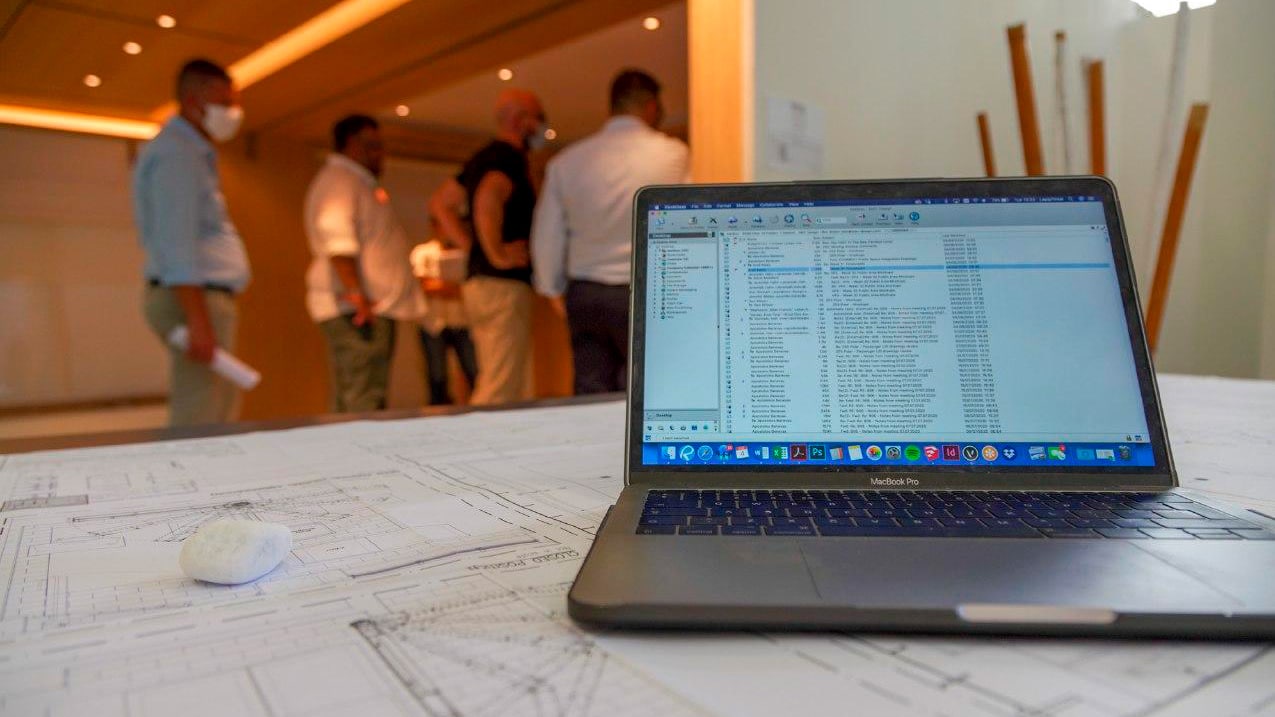

The new technologies we have adopted, in the spirit of Industry 4.0, allow designers and workers, engineers and artisans, to work side by side to achieve the full integration and coexistence of creative, engineering, and manual skills. This is made possible with the help of new software that processes an infinite amount of data in real-time, ensuring that every construction detail perfectly matches the design requirements. It is a perfect balance between man and machine, between numerical precision and artisanal wisdom.

Thanks to an internal management system, all the processing processes in the workshops generate a wealth of data that is analysed in real-time by advanced big data analysis software. The interconnected machinery, through IoT, provides feedback that allows controllers to verify the accuracy of every detail, optimizing processing times and, consequently, the delivery times of the manufactured products.

Large ships, high standards, and reduced timeframes

Thanks to these new technologies, all the work remains in memory and can be recalled. This allows us to replicate the best practices already tested for creating interiors for the large and luxurious cruise ships we are proud to work on, from the new creations of Virgin Voyages to the timeless Princess Cruises or Carnival Cruise.

If Industry 4.0 has already significantly impacted the shipbuilding industry, today, all related sectors must also adapt to keep up and ensure the required performance and quality standards. This is the challenge we have accepted, along with the opportunity to acquire, during this digitalisation process, the flexibility and sustainability that allow us to thrive as contractors and constantly improve.